2024

T. Hastings, J. Paramore, B. Butler, R. Arroyave, D. Khatamsaz, and D. Allaire, “Interoperable Batch Bayesian Optimization Techniques for Efficient Property Discovery of Metals,” in TMS Annual Meeting and Exhibition, Orlando, FL, USA, 2024.

1 Bush Combat Development Complex, Texas A&M University System

2 Department of Materials Science and Engineering, Texas A&M University

3 DEVCOM Army Research Laboratory

Abstract:

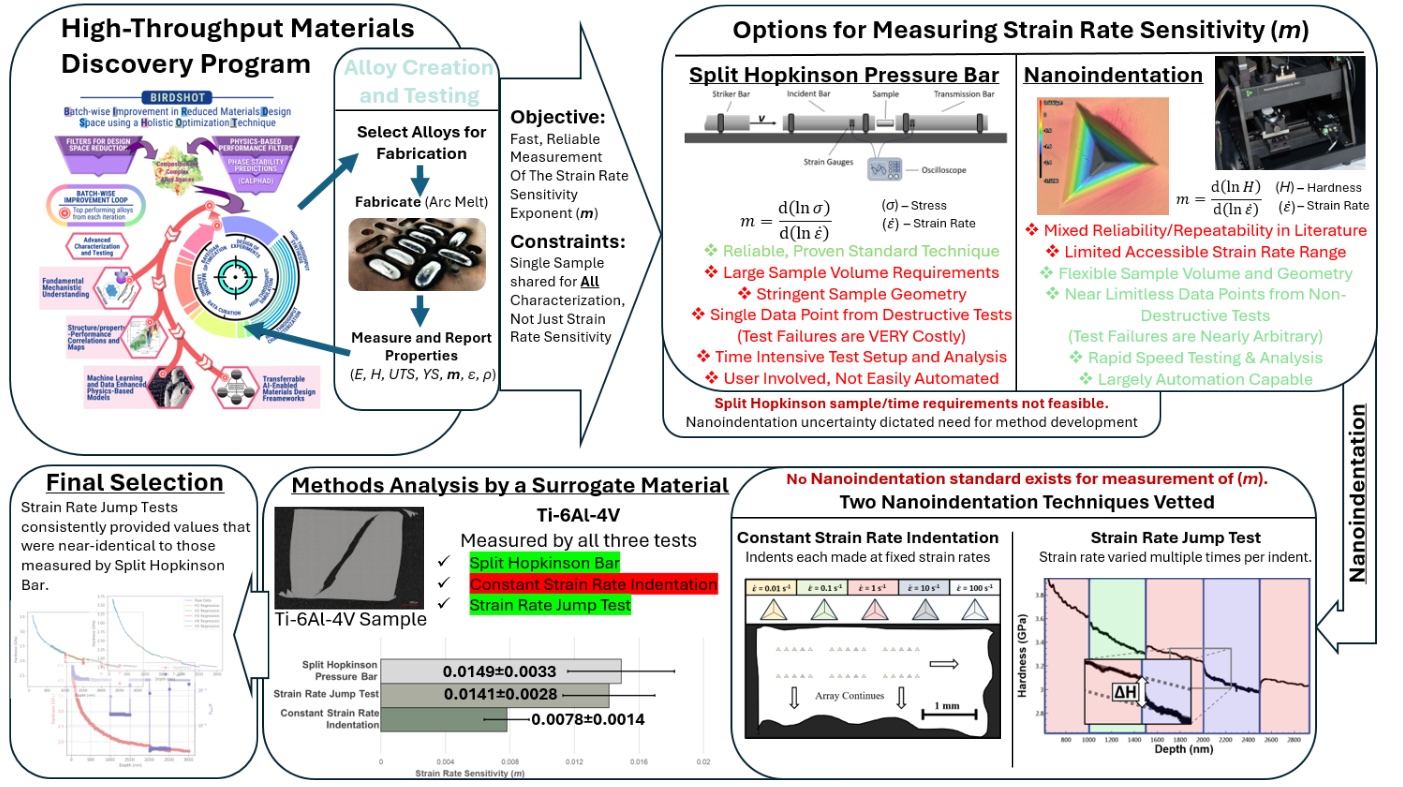

Many next-generation applications of titanium alloys in the defense, transportation, and energy sectors require reliable mechanical performance at elevated strain rates. However, reliably assessing mechanical properties over a wide range of strain rates can be cumbersome using bulk methods (e.g., Kolsky/split-Hopkinson pressure bar testing), thereby slowing innovation in both alloy and processing design. In this study, several nanoindentation techniques for assessing strain rate sensitivity (SRS) were investigated and compared with respect to reliability, rapidity, and quality of data produced. The material of interest was Ti-6Al-4V produced via advanced powder metallurgy methods, which has been previously shown to exhibit promising high strain rate properties during bulk testing. Correlations between the strain rate sensitivity measured via the various nanoindentation methods and bulk testing will be presented. Furthermore, the potential for microscale mechanical characterization methods to accelerate discovery of new titanium alloys and processing routes will be discussed.

Rapidly Assessing Strain Rate Sensitivity of Titanium Alloys via Nanoindentation