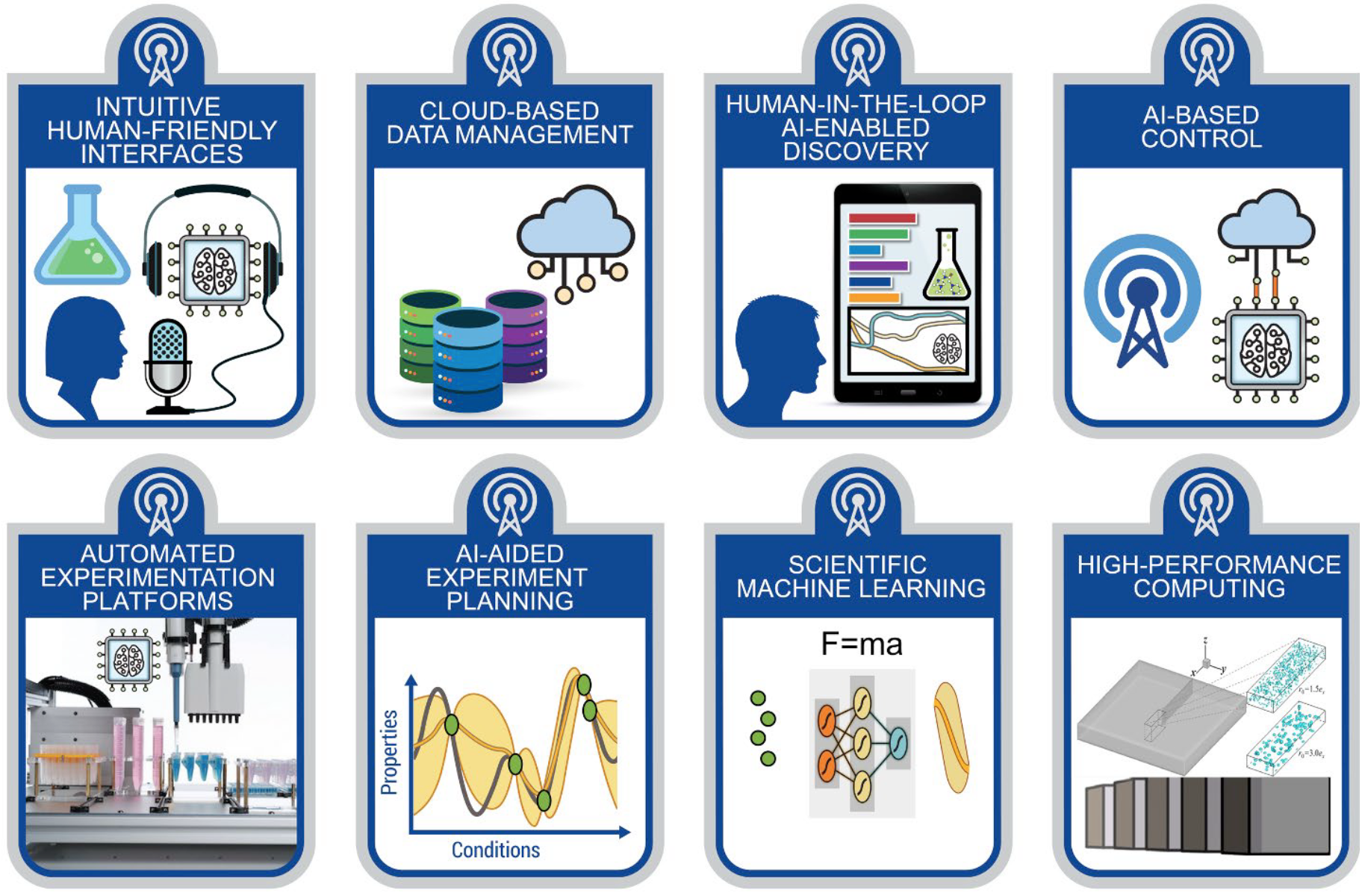

In the Long term, We envision BIRDSHOT as the kernel of a cyber-physical alloy discovery platform that combines, in a highly integrated manner, the rapid and automated synthesis, thermomechanical processing, characterization, and simulation to explore complex materials design spaces in an accelerated way.

- Discovery Workflow and Information Management: The BIRDSHOT integrated workflow aims to accelerate materials development by optimizing a highly collaborative workflow for efficiency, accuracy, and scientific advancement. It promotes open science among geographically dispersed teams, focusing on seamless integration of design, synthesis, characterization, and modeling components for targeted material development as well as effective coordination and FAIR data management.

- AI/ML-Driven Materials Design: Our AI/ML-driven design framework (i) combines Machine learning (ML)-enhanced physics-based models, phase stability analysis, and advanced alloy search schemes to efficiently identify the feasible regions of the materials design space; (ii) incorporates prior knowledge, transforming it into actionable decision-support for materials discovery; (iii) fuses simulations and experiments to obtain efficient ML models for PSPP relations; (iv) utilizes Bayesian Optimization (BO) to make globally optimal iterative decisions on where to explore/exploit the design space to maximize expected performance gain; (v) leverages the newly developed Batch BO that enables iterative exploration/exploitation of the materials space by evaluating multiple alloy chemistries and/or microstructures at once while considering multi-objectives and constraints.

- HTP Synthesis: Historically, the development of new bulk alloys has been slow due to the challenges associated with bulk alloy synthesis and highly user–dependent materials characterization methods. On the other hand, current high throughput synthesis methods tend to be based on thin-film technologies that are unsuitable for discovering bulk materials. We use two synthesis routes: a highly integrated Vacuum Arc Melting (VAM)-based synthesis and characterization setup at Texas A&M University and the Directed energy deposition (DED)-based setup at UC San Diego.

- HTP Characterization: A significant challenge in any HTP approach to materials discovery comes from the high time and cost of conventional characterization protocols. While there has been some work on the HTP characterization of the mechanical response of combinatorial materials libraries, investigation of the mechanical response of materials at the extremes, i.e., high strain-rate and high temperatures, remains a significant challenge.